Electronics Design Support

Electronics Design Support is a defining value-add from your Electronics Manufacturing Services (EMS) partner and for TechPoint, it’s a key differentiator helping our customers accelerate product development, bridge concept and manufacturability, improve performance and reliability, reduce time-to-market and cost as well as fostering innovation through partnership. TechPoint's Electronics Design Support encompasses the range of services shown below:

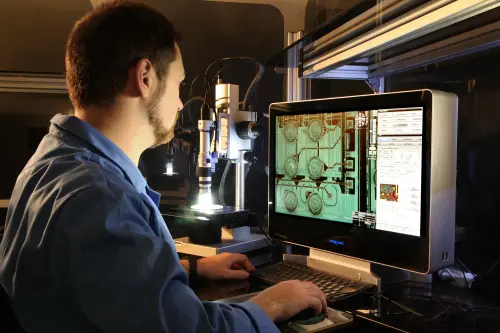

Board Layout

Board Layout

Designing a circuit board layout is a crucial step in electronics development, ensuring that components are arranged efficiently for performance and manufacturability. Our service would typically involve the following steps:

PCB Design - using Altium Designer

Component Placement – arranging components logically to minimise signal interference

Routing Traces – connecting components using copper traces while following design rules

Power & Ground Planes – ensuring stable power distribution and signal integrity

Design Rule Check (DRC) – validating the layout for errors before manufacturing

Design for Excellence (DFX)

Design for Excellence (DFX)

DFX is a strategic approach to product development that optimises various aspects of design to enhance efficiency, quality and sustainability. It incorporates multiple principles, each focusing on a specific area of improvement including:

Design for Manufacturing (DfM): ensures products are easy and cost-effective to manufacture

Design for Assembly (DfA): simplifies assembly processes to reduce time and labour

Design for Reliability (DfR): enhances durability and long-term performance

Design for Sustainability (DfS): focuses on eco-friendly materials and energy efficiency

Design for Cost (DfC): minimises production expenses while maintaining quality

Design for Testability (DfT): improves ease of testing to ensure functionality and compliance

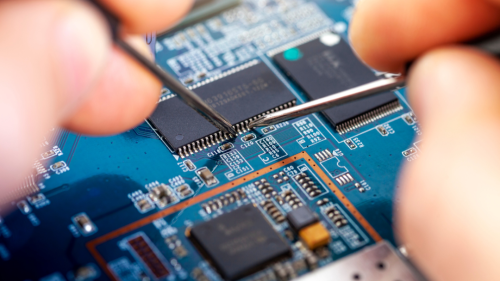

Design for Manufacturing & Cost Optimisation (DfM & DfC)

Design for Manufacturing & Cost Optimisation (DfM & DfC)

DfM & DfC services focus on refining product designs to enhance manufacturability while minimising costs. These services ensure that products are efficient to produce, maintain high quality and remain cost-effective throughout their lifecycle. Key Aspects of DfM & DfC include:

Material & Component Selection: choosing cost-effective, high-quality materials that are readily available

Manufacturability Verification: ensuring designs are optimised for efficient production processes

Lead-Time Reduction: streamlining workflows to accelerate production and delivery

Process Optimisation: enhancing assembly techniques to reduce labour and material waste

Cost Analysis & Reduction: identifying areas where expenses can be minimised without compromising quality

Design for Supply Chain (DfSC)

Design for Supply Chain (DfSC)

This strategic approach optimises product design to enhance efficiency, cost-effectiveness and resilience within the supply chain. It ensures that products are designed with logistics, procurement and distribution in mind, reducing delays and minimising costs. Key principles of DfSC include:

Material & Component Selection: choosing readily available, cost-effective and high-quality materials

Manufacturability & Lead-Time Reduction: designing products that streamline production and minimise delays

Supplier Integration: ensuring compatibility with supplier capabilities and reducing dependency on scarce components

Standardisation & Modularity: using interchangeable parts to simplify sourcing and assembly

Sustainability & Compliance: meeting environmental and regulatory standards while optimising supply chain efficiency

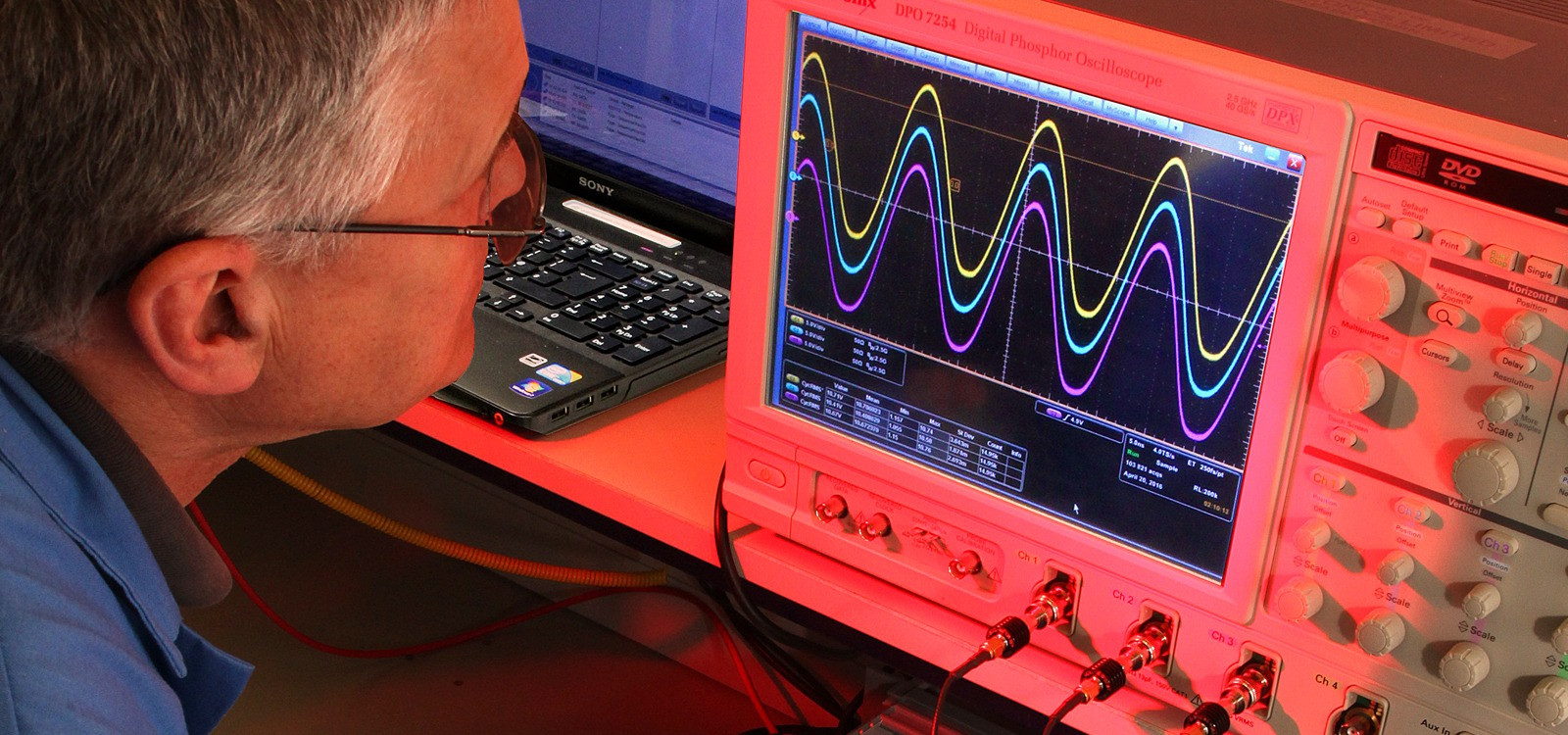

Design Verification

Design Verification

Our Electronics Design Verification service ensures that electronic designs function correctly before production and typically includes:

Simulation-Based Verification: using tools such as Valor

Formal Verification: ensuring logical correctness without requiring test vectors

Power Analysis & Performance Testing: evaluating efficiency and stress conditions

Compliance Testing: verifying adherence to industry

Feasibility Analysis

Feasibility Analysis

Our feasibility analysis assesses whether your concept can be successfully implemented. It typically examines:

Technical Feasibility – whether the necessary technology and skills exist

Economic Feasibility – evaluating costs, funding and profitability

Operational Feasibility – determining if the project aligns with manufacturing processes

Legal & Regulatory Feasibility – ensuring compliance with laws and industry standards