Prototype Services

Our flexible prototype services accelerate your path from concept to finished product, enabling quick, precise iterations that keep development moving fast. With rapid prototyping, you can test, refine and perfect designs in record time, ensuring each version meets your needs. Our expert engineers and advanced technology make it easy to adapt and troubleshoot, reducing time-to-market and setting you up for a smoother production launch. Find out more about TechPoint's prototype services below:

Cost Optimisation

Cost Optimisation

Cost optimisation is essential for balancing performance, reliability and affordability. It involves strategic decisions in design, manufacturing and procurement to reduce expenses without compromising quality. Key strategies for cost optimisation include:

Component Selection: choosing cost-effective alternatives without sacrificing functionality & quality

Design Efficiency: simplifying PCB layouts to minimise material and assembly costs

Manufacturing Process Optimisation: using automated testing and efficient soldering techniques like vapour phase, nitrogen and conventional reflow

Supply Chain Management: negotiating better pricing and sourcing components strategically

Simulation-Driven Design: using digital simulations to reduce prototyping costs and shorten time to market

Standardisation: using off-the-shelf components where possible to avoid custom manufacturing expenses

Fast Track Electronics

Fast Track Electronics

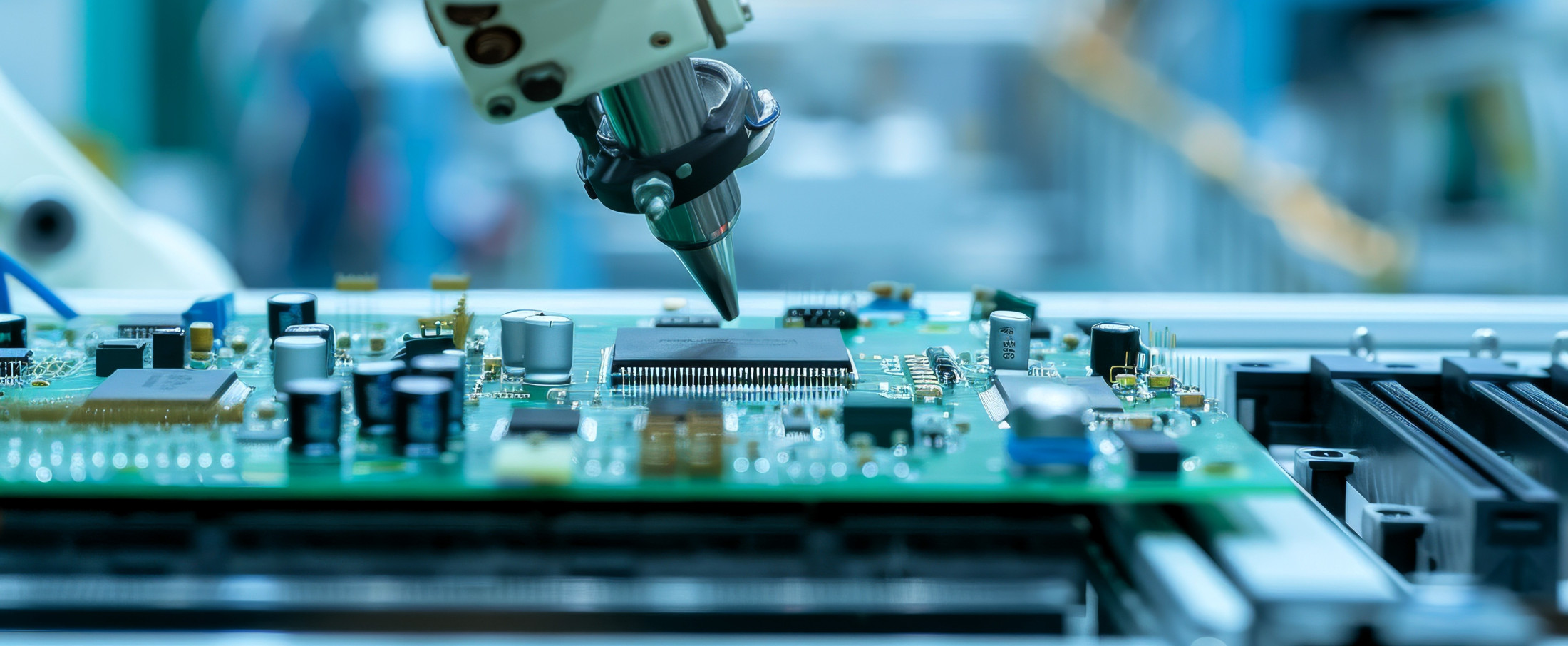

This refers to our services that are optimised to accelerate the development and manufacturing of electronic products. We offer rapid prototyping, design verification and fast-turn PCB assembly to help customers bring their products to market quickly. Our service offers:

Rapid Prototyping & small batch assembly: speeding up the design and testing phase with builds completed in 5 to 10 working days from material clearance

PCB Design & Layout: optimising circuit board designs for efficiency

Surface Mount Technology (SMT): advanced assembly techniques for compact electronics

Quality Control: ensuring reliability and performance

Lead-time Reduction

Lead-time Reduction

Lead-time reduction is crucial for improving efficiency, minimising delays and ensuring timely product delivery. TechPoint uses various strategies to streamline procurement and manufacturing processes including:

Optimised Supply Chain Management: strengthening supplier relationships and diversifying sourcing options to mitigate delays

Component Stockpiling: pre-purchasing critical components to avoid shortages and long lead times

Design for Availability: selecting readily available components during the design phase to prevent bottlenecks

Automated Procurement & Forecasting: using AI-driven tools to predict demand and optimise inventory levels

Local Sourcing & Manufacturing: reducing dependency on overseas suppliers to shorten transportation times

Manufacturability Verification

Manufacturability Verification

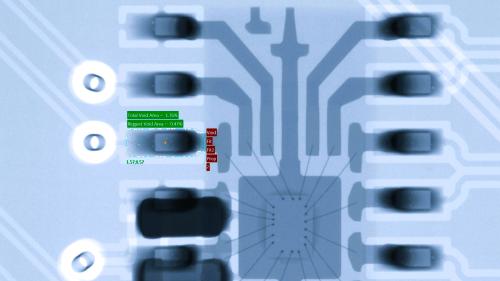

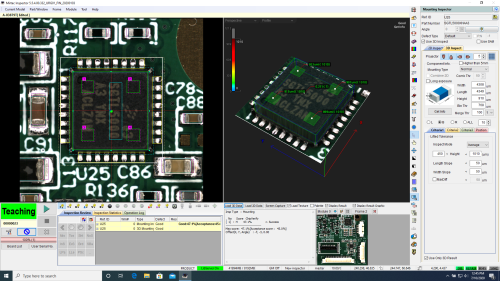

Manufacturability verification in electronics ensures that a product design can be efficiently and reliably produced in scale. It helps identify potential manufacturing issues early, reducing costs and improving yield. Key aspects of our manufacturability verification include:

Design for Manufacturing (DFM): optimising PCB layouts and component placement to streamline production

Automated Testing & Inspection: using tools like 3D Automatic Optical Inspection (AOI) and 3D X-ray Inspection (AXI) to detect defects

Material & Process Validation: ensuring compatibility with soldering techniques such as vapour phase, nitrogen and conventional reflow

Failure Mode Analysis: identifying potential weaknesses to enhance product reliability

Supply Chain Coordination: collaborating with manufacturers to align design with production capabilities

We also have experience in Production Part Approval Process (PPAP) for automotive and other industries

Material & Component Selection

Material & Component Selection

Material and component selection in electronics is a crucial process that impacts performance, reliability and cost-effectiveness. Choosing the right materials ensures optimal thermal management, electrical conductivity and mechanical durability. Some key considerations include:

Thermal Conductivity: materials like Rogers RT laminate are ideal for high-power applications due to their ability to dissipate heat efficiently

Electrical Properties: high-conductivity metals such as copper and silver are commonly used in wiring and components

Mechanical Strength: polymers, ceramics and composites provide durability in harsh environments

Component Efficiency: low Equivalent Series Resistance (ESR) capacitors and low DC Resistance (DCR) inductors help minimise power losses

Semiconductor Materials: silicon remains dominant but alternatives like Silicon Carbide (SiC) are gaining traction for high-voltage applications

Mechanical Prototyping

Mechanical Prototyping

This is a crucial step in product development, allowing engineers to test form, fit and function before moving to full-scale production. It helps refine designs, validate concepts and ensure manufacturability. Some common mechanical prototyping methods that we use include:

3D Printing: fast and cost-effective for early-stage design verification

CNC Machining: high-precision prototyping for rugged and functional parts

Vacuum Casting: ideal for short-run batch testing with realistic material properties

Sheet Metal Fabrication: used for enclosures and structural components

Injection Moulding: suitable for high-fidelity prototypes that mimic final production

New Product Introduction (NPI) Services

New Product Introduction (NPI) Services

TechPoint’s NPI services help businesses bring new electronic products to market efficiently by streamlining design, prototyping, testing and manufacturing. Our comprehensive NPI solutions include:

Engineering Samples & Prototyping: early-stage validation to refine designs

First Article Inspection (FAI): ensuring initial production meets quality standards

Design for Manufacture (DFM) & Design for Test (DFT): optimising designs for efficient production and testing

Supply Chain Qualification: managing component sourcing and risk assessment

EMC Qualification Assistance: ensuring compliance with electromagnetic compatibility standards

Product/Design Verification

Product/Design Verification

This is a critical process that ensures a product meets its intended specifications and functions correctly before volume production. It involves rigorous testing and validation to identify design flaws early, reducing costly errors and improving reliability. Some key aspects of our service include:

Functional Testing: ensuring the product performs as expected under various conditions

Design for Manufacturing (DFM): checking whether the design is optimised for efficient production

Simulation & Prototyping: using digital models and physical prototypes to validate performance

Compliance Testing: verifying adherence to industry standards and regulations

Failure Analysis: identifying potential weaknesses and improving durability

Automated Tools: we use software such as Valor to streamline design verification

Small Batch Production

Small Batch Production

TechPoint’s small batch production is ideal for prototyping, niche products and low-volume manufacturing. It offers flexibility, cost efficiency and faster turnaround times compared to mass production. Some key advantages include:

Rapid Prototyping: allows for quick iterations and design validation

Cost-Effective Manufacturing: reduces upfront investment and minimises waste

Design Flexibility: easier to implement modifications before scaling up

Lower Risk: helps identify potential issues before committing to large-scale production