Supply Chain Solutions

Your supply chain plays a crucial role in shaping the success of your entire organisation. That’s why you need an EMS partner capable of navigating and mastering the complexities of everything from component sourcing to full traceability, delivering an end-to-end electronic supply chain service, from initial concept to market impact. TechPoint is trusted by global brands and independent businesses alike, supporting innovation throughout the entire product development process. Our team integrates seamlessly with yours, ensuring a deep understanding of your objectives and challenges. With our expertise and technical know-how, we’ll help you bring high-quality products to market on time and within budget. You can find out more about these solutions below:

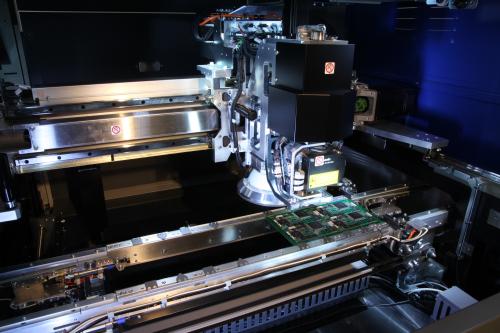

Bespoke Material Kitting

Bespoke Material Kitting

This service streamlines your supply chain by pre-assembling individual components into ready-to-use kits tailored to specific production needs. This approach enhances efficiency, reduces waste and simplifies inventory management. Key features include:

Custom Kit Assembly: components are grouped based on specific manufacturing or assembly requirements

Inventory Optimisation: reduces excess stock and ensures critical materials are readily available

Supply Chain Efficiency: minimises handling time and improves workflow

Cost Control: helps manage procurement costs by consolidating materials into optimised kits

Quality Assurance: ensures consistency and accuracy in component selection

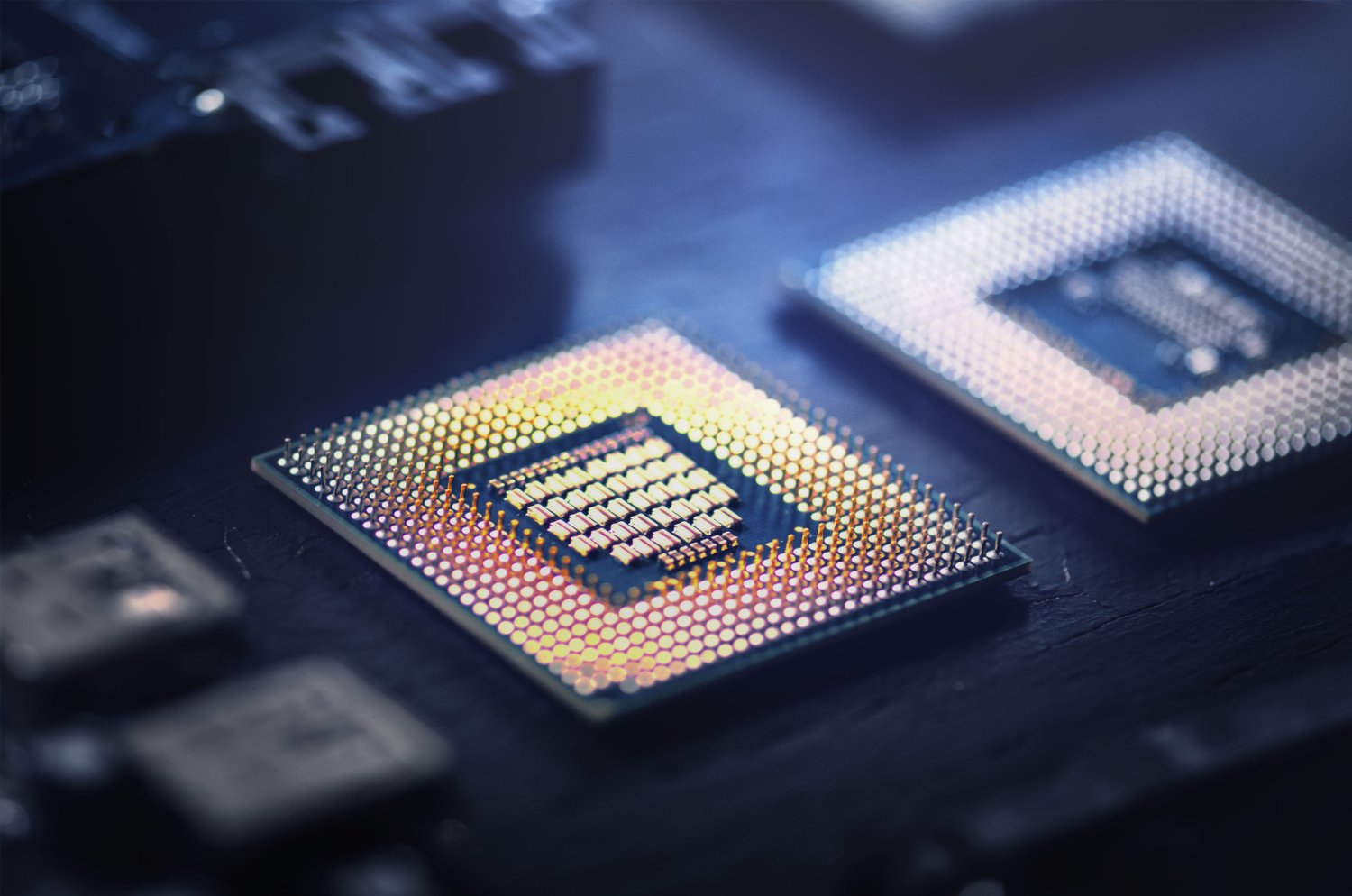

Counterfeit Avoidance

Counterfeit Avoidance

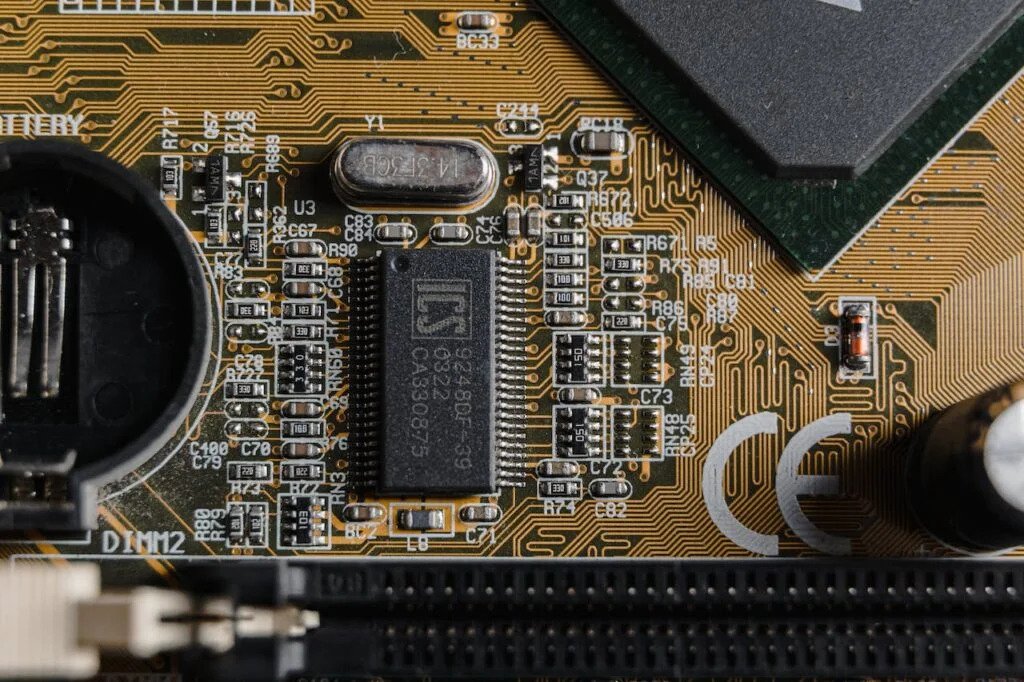

Counterfeit avoidance is crucial in industries such as aerospace, automotive, medical and military electronics where fake components can lead to safety risks, financial losses and reputational damage. Our key strategies for counterfeit avoidance include:

Supplier Verification – working only with trusted suppliers and authorised distributors to ensure authenticity

Traceability & Documentation – maintaining detailed records of component origins, certifications and quality checks

Quality Control & Testing – using advanced inspection techniques like X-ray analysis, electrical testing and material verification.

Regulatory Compliance – following industry standards such as AS5553 (for electronic components) and ISO 9001 to mitigate counterfeit risks

Employee Training – educating staff on identifying counterfeit materials and reporting suspicious components

Technology Solutions – implementing RFID tracking, blockchain and AI-powered detection systems to enhance security

Demand Planning & Management

Demand Planning & Management

This service helps businesses forecast, optimise and align inventory with market demand to improve efficiency and reduce costs. Key aspects include:

Forecasting & Analytics: using historical data and AI-driven models to predict future demand

Inventory Optimisation: ensuring stock levels align with demand to prevent shortages or excess inventory

Supply Chain Coordination: synchronising procurement, production and distribution for seamless operations

Market Trend Analysis: identifying shifts in customer behaviour and adjusting strategies accordingly

Risk Management: mitigating disruptions by planning for supply chain uncertainties

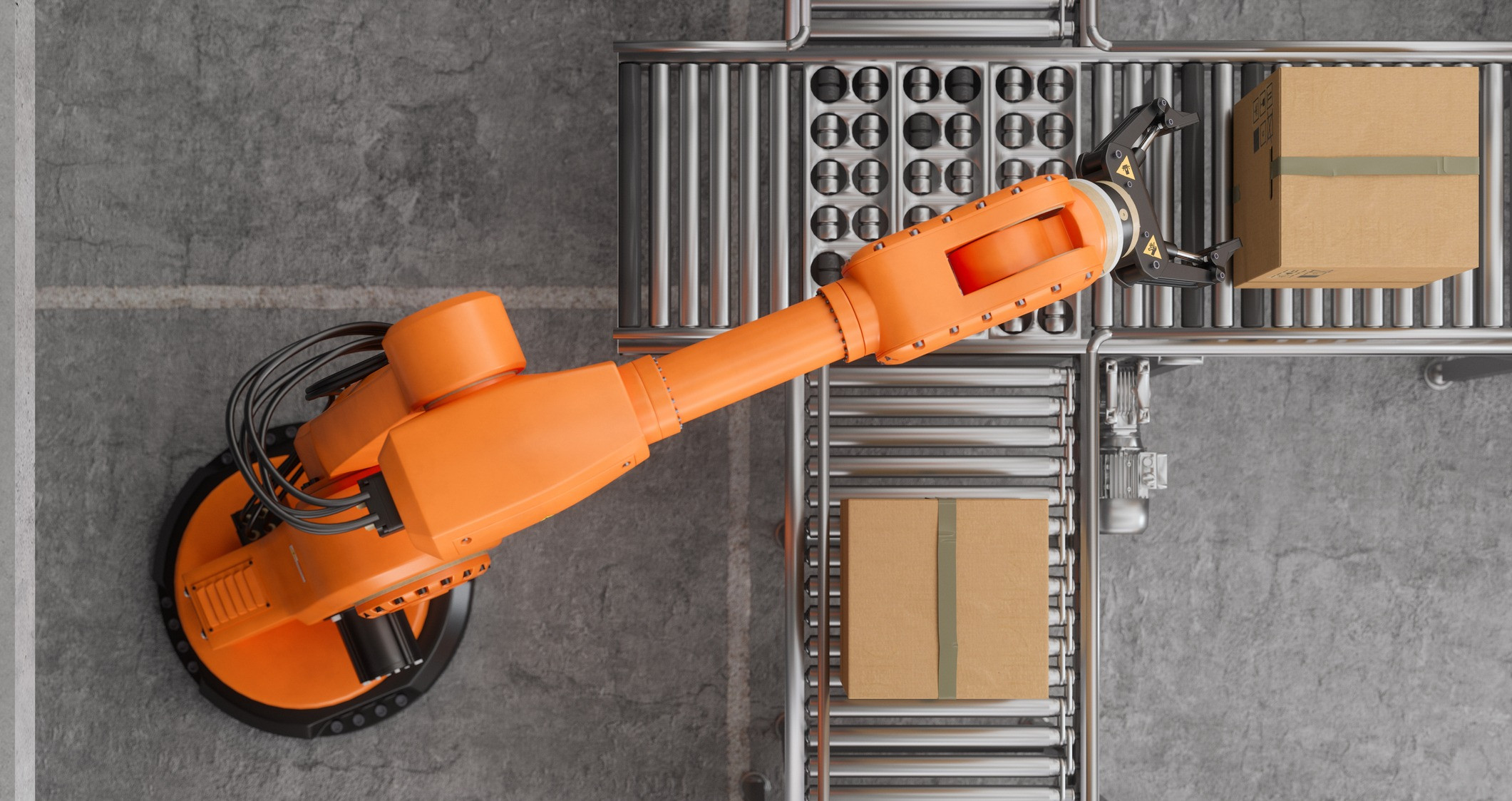

Fifth-Party Logistics (5PL)

Fifth-Party Logistics (5PL)

5PL is the next level of logistics management where TechPoint oversees a customer’s entire supply chain, integrating multiple logistics service providers and leveraging advanced technologies like AI, IoT and Big Data analytics. Key Features of 5PL include:

End-to-End Supply Chain Management – unlike 3PL and 4PL, 5PL providers manage all logistics operations, often for multiple clients simultaneously.

Technology-Driven Optimisation – using AI, machine learning and automation to enhance efficiency, reduce costs and improve delivery speed

Omnichannel Logistics – supporting businesses operating across multiple sales channels, ensuring seamless order fulfilment

Scalability & Flexibility – helping customers adapt to changing market demands and global trade complexities

With the rise of e-commerce and global trade, businesses need smarter logistics solutions. As a 5PL specialist, TechPoint helps customers streamlines operations, reduce costs and ensure smooth supply chain management.

Full Traceability

Full Traceability

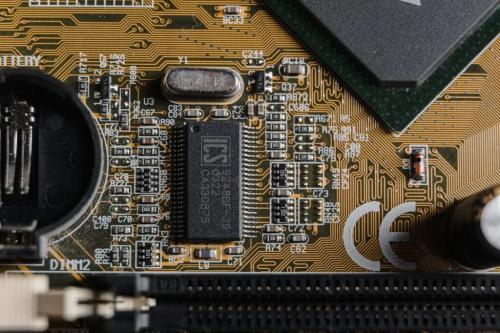

Our full traceability services ensure that every component, material and process in a supply chain can be tracked from origin to final product. This enhances quality control, regulatory compliance and risk management which is crucial given the growing issue of counterfeit components in electronics manufacturing. Key aspects of traceability in electronics include:

Component Tracking: every electronic part, from microchips to resistors, is logged with LOT number to trace its source and serial number to trace usage

Quality Assurance: traceability helps detect defects early, preventing faulty products from reaching customers

Compliance & Regulations: industries such as aerospace, automotive, medical and military electronics require strict traceability for safety and legal compliance and follows AS9120 standard.

Product Recalls & Warranty Claims: if a defect is found, manufacturers can quickly identify affected batches and take corrective action

KANBAN Solutions

KANBAN Solutions

Kanban Solutions refers to tools and methodologies that help businesses manage workflows efficiently using the Kanban system. This system, originally developed by Toyota, focuses on visualising tasks, limiting work in progress and optimising flow to improve productivity. Key Benefits of Kanban Solutions include:

Improved Workflow Visibility – tasks are displayed making it easy to track progress

Reduced Bottlenecks – helps teams identify and resolve workflow inefficiencies

Enhanced Collaboration – encourages transparency and teamwork

Flexibility & Scalability – works for small teams and large enterprises alike

Obsolescence Management

Obsolescence Management

This is a crucial strategy for ensuring long-term reliability and sustainability in electronic systems. It involves proactively identifying and mitigating risks associated with ageing or discontinued components, preventing supply chain disruptions and reducing costly redesigns. Some of the key strategies we offer for managing electronic component obsolescence include:

Proactive lifecycle management: monitoring the availability and lifecycle status of components to anticipate obsolescence risks early

Supply chain visibility: maintaining strong relationships with suppliers to ensure access to critical components even when they are phased out

Alternative sourcing: identifying substitute components or redesigning systems to accommodate newer technologies

Inventory management: stocking essential components to mitigate the impact of sudden discontinuations

Regulatory compliance: adapting to environmental and safety regulations that may affect component availability

Product Lifecycle Management

Product Lifecycle Management

Product Lifecycle Management (PLM) is a strategic approach to managing a product from its initial concept through design, manufacturing, use and eventual retirement. It helps businesses streamline processes, improve efficiency and maximise product success. Key Stages of PLM are:

Concept & Development – identifying market needs, designing the product and planning production

Introduction – launching the product, marketing strategies and initial customer adoption

Growth – increasing sales, optimising production and expanding market reach

Maturity – Peak sales, cost management and potential product improvements

Decline – Phasing out the product, transitioning to new models, or discontinuation

Benefits of PLM include:

Improved Collaboration – Connects teams across design, engineering and manufacturing.

Cost Reduction – helps optimise production and minimise waste

Faster Time-to-Market – streamlines development and launch processes

Regulatory Compliance – ensures adherence to industry standards and safety regulations

Better Product Quality – enables tracking and improvements throughout the lifecycle

Return Materials Authorisation (RMA) Management

Return Materials Authorisation (RMA) Management

TechPoint’s RMA service is a structured process that customers use to handle product returns efficiently. It ensures that returned items are properly tracked, inspected and processed, whether for repair, replacement or refund. Key aspects of our RMA management include:

Authorisation Process – customers must obtain approval before returning items, ensuring eligibility and preventing fraudulent returns

Tracking & Documentation – each return is logged with details like reason, condition and resolution to maintain transparency

Inspection & Quality Control – returned items undergo testing to determine whether they can be repaired, replaced, or refunded

Inventory & Cost Management – helps customers optimise stock levels and reduce financial losses from returns

Customer Satisfaction – our well-managed RMA process improves customer trust and loyalty by providing a seamless return experience

Supplier Consolidation

Supplier Consolidation

Supplier Consolidation is a strategic approach to supply chain management that involves reducing the number of suppliers a company works with. This helps streamline procurement, improve efficiency and reduce costs. Key benefits of supplier consolidation include:

Cost Savings: fewer suppliers mean better bulk pricing and reduced administrative costs

Improved supplier Relationships: stronger partnerships lead to better service and reliability

Simplified Procurement: less complexity in managing multiple vendors

Supply Chain Efficiency: reduces lead times and enhances coordination

Risk Management: minimises disruptions by working with trusted suppliers

Supply Chain as a Service (SCaaS)

Supply Chain as a Service (SCaaS)

SCaaS is a model where companies outsource their supply chain operations to a partner like TechPoint with the appropriate expertise. This approach helps our customers to streamline logistics, improve efficiency and reduce costs while maintaining flexibility in sourcing and distribution. Some key benefits of SCaaS in electronics include:

End-to-end supply chain management: TechPoint handle procurement, inventory management, logistics and distribution

Supply chain visibility: our digital platforms offer real-time tracking of orders, inventory and shipments

Risk mitigation: we help manage shortages, excess inventory and disruptions

Scalability: customers can adjust supply chain operations based on demand fluctuations

Technology integration: we utilise AI and analytics to enhance forecasting and decision-making

Tail Spend Management

Tail Spend Management

This refers to controlling and optimising the high-volume, low-value purchases that often go unmanaged within an organisation. These transactions typically make up 80% of suppliers but only 20% of total procurement spend - a concept based on the Pareto Principle. Tail spend matters because:

Cost Savings – unmanaged spending can lead to inefficiencies and missed savings opportunities

Supplier Consolidation – reducing the number of suppliers improves procurement efficiency

Risk Reduction – helps prevent fraud, compliance issues and unnecessary purchases

Strategic Sourcing – enables better negotiation and supplier relationships

TechPoint use the following tools to manage tail spend effectively

Data Visibility – using analytics to track and categorise spending patterns

Automation & AI – implement digital tools to streamline procurement and reduce manual oversight

Supplier Rationalisation – consolidating vendors to improve pricing and efficiency

Policy Enforcement – establishing clear procurement guidelines to prevent maverick spending

Vendor Managed Inventory (VMI) Solutions

Vendor Managed Inventory (VMI) Solutions

VMI is a supply chain strategy where we take responsibility for managing inventory levels at our customer's location. This approach helps streamline operations, reduce stock shortages and optimise replenishment. Key Features of our VMI Solutions are:

Automated Inventory Replenishment: suppliers monitor stock levels and restock as needed

Demand Forecasting: uses real-time data to predict future inventory needs

Reduced Stockouts & Overstocking: ensures optimal inventory levels, minimising excess stock and shortages

Improved Supplier-Customer Collaboration: strengthens relationships through shared data and proactive inventory management

Cost & Efficiency Optimisation: reduces carrying costs and improves supply chain responsiveness